Search the Community

Showing results for 'coal pit lane'.

-

When was this built and when did it close?

Jim Aizlewood replied to Sheffield History's topic in Sheffield History Chat

I remember when this was being built that there was a long delay due to them finding a coal seam which they had to dig out, many years later I was going down the ramp in a very old transit van with an ignition fault when it backfired just before I went under the footbridge which was full of people eating their suppers sadly most of them lost that supper due to the loud bang and big flash from the exhaust. -

George Thorpe ( a local )had the coal drops for a time in the 70's making and repairing pallets, and I was told the Simcox's (local ) built the industrial units on top after Fieldhouse Brothers had used it as a tip. My memories of Anlaby Street as a kid were painful, as I was making my way along the bottom of the Don wall, somebody decided ( my auntie as it turned out ) decided to empty her teapot over the wall of Brough Street and the contents landed on me, still hot.

-

I was down there last year, how scruffy it all is now. The photo of the school shows just how well built they were in those days and brought back many happy memories. Incidentally "Waterside Echo" was the title of our school magazine. As I started school in 1949 Neepsend Station was being demolished, the railway bridge over Parkwood Road went two or three years later. Not sure about the coal shutes and the dust,but while they were in operation as soon as the gates were shut every one was out with brushes and shovels, "cleanest road in Neepsend." Roy was in my class, I took the Central Tech exam with him along with Keith Hackett and Frank Wheldon. result 3-1 to them. I don't remember much about the practice for the Queens visit but remember seeing her at the football ground. The last time I was speaking to Roy would have been in the 80s, he had his own building firm then and was putting a large detached house up at the bottom of Industry Street Walkley. W/E.

-

Just browsing around for more photos and info on the school. The high wall and coal bunkers look interesting, so wonder if anyone has any recollection of them in use? I see the railway siding on the 1923 map, when the bunkers were in use, but I bet the residents on Hoyland Road opposite were always covered in coal dust?! The school boys entrance gate is all but hidden by the tree now, but an interesting story in the link and maybe you knew Roy Priest from 1953? http://www.geograph.org.uk/photo/1035068 http://www.geograph.org.uk/photo/1035144 Another vibrant, bustling corner of the city now gone, except for a few industrial units and some echoes of the past?

-

Dose anyone remember their Gran having a container of 'COAL CRYSTALS'. My Gran had them in an up turned glass jelly mould, on top of her big radio, sat on a cupboard. ( I guess out of the way of little fingers ) Every so often she would get them down to 'feed them', she used an Eye Dropper, with some sort of liquid in, which I was allowed to drip over the Crystals, then we put drips of Red and Blue ink on the top. A couple of weeks later, we would get them down to find more beautiful Pink and Violet Crystals had grown from the coal in the bottom. It always fascinated me how it happened.

-

St. Mary's Walkley

Paul Connor replied to Paul Connor's topic in Sheffield Churches & Religious Buildings

I was born at number 2 Duncombe Street in 1949. It was the corner house at the bottom if the street. We moved to Rivelin Valley when I was six or seven, but my grandparents still lived in that house for many years after. Two up two down, cellar ( I can remember the coal man delivering ) and attic, outside toilet. No bathroom, used to get the tin bath out. It had a coal fire and that fuelled the oven. I can still remember my grandmother baking bread. Used to walk from Hollins Lane to the church three times on Sunday's. Choir practice Friday night. -

I remember the coal man delivering in the late 50's / early 60's around Pitsmoor, Brunswick Road, Nottingham Street Marcus Street, Spital Street, area I think his yard was on Neville Street, but not sure. In fact I can still remember his face. He was a mate of my dad's, and sometimes my Brother and I would sit in the cab when he went around collecting his money. But for the life of me I can't remember his name and I don't have any photo's of him. I wonder if any one on here can remember his name or has any photo's ?

-

I looked on the coal maps and there's nothing in the vicinity. The tunnel is also roughly following the contour of the hill (or is at least perpendicular to it at this point) which a drift never would If someone were able to get a photo showing the full cross section of the tunnel, that would tell a lot Edit: You know what - it could even be the 'coal hole' for the original Ash Leigh house ? (assuming it doesn't go all the way under the road)

-

I’m sure we can cross mining activity off the list. Any coal found that close to the surface ( if you can even find it that close?) would simply be open casted. I’m no expert and may have this wrong, but seem to remember reading that the seams of coal run slightly down hill, as such in South Yorkshire.... Cap House just north of Barnsley had one seam at a depth of 140m were as Dinnington was far deeper. Given that, I think Handsworth would be more famous as a mining town with if it had a 4foot deep seam.

-

He used to deliver to our house on the Manor right up till the 80's when the council fitted gas central heating. I remember wondering if we were going to get coal delivered during the coal strike of 1984. Craig complained about how the council switching people to gas central heating was killing his business. However he was getting very pricey with his coal.

-

26 Market Street H.& W.T. Maw -coal dealers.

-

I really can't recall a coal merchant having been based on Market Street, in the 1960's, and I was around then. I remember W. Craig, but I am certain that they were based at 148, Sheffield Road, just above where Woodhouse West End School used to be. I also remember Wilf Maw, but I think that he came from Ecclesfield way, and also Arthur Dixon, based on Olivers Mount. Will really have to think about this one, as I don't recall anyone actually having being based on Market Street.

-

Does the name Craig ring a bell? A Coal man of that name delivered on the Manor estate in the fifties.

-

Does anyone know of a Coal dealers in Sheffield around the woodlouse area in the 1960s? I believe the dealer operated from a yard in Market street. I would be really interested in any information Thanks

-

MY FAREWELL TO THE SHEFFIELD MANCHESTER ELECTRICS - CONGREVES 1970

Lemmy117 replied to RLongden's topic in Sheffield Buses, Trams and Trains

There were two types of electric locos used, the EM1's later class 76 that ended up running in pairs, and the EM2's that would have been designated class 77. The 76's ran until closure of the line on the coal traffic. The class 77's were designed as express passenger locos, but deemed surplus to requirements by 1968. There were only 7 locos in the class and were all sold to the Dutch railways. Two of them have returned to Britain, one at the Midland Railway centre at Butterly and one at the Museum of Science and Industry in Manchester. -

MY FAREWELL TO THE SHEFFIELD MANCHESTER ELECTRICS - CONGREVES 1970

Old rider replied to RLongden's topic in Sheffield Buses, Trams and Trains

Ah the excursions I was taken on as a child from Wadsley Bridge Station to visit Belle View Zoo on this line. A little historical note. The electrification of this route was proposed prior to WW2 and the first electric loco was built under Sir Nigel Gresley in 1939 and was stored at Doncaster until after D Day. After the invasion this loco was used to aid the war effort by running on continental DC electrified lines of the low countries (France had gone for AC electrification pre war) . On its return to the UK it was named Tommy in recognition of its war record. The DC system allowed the locos to act as generators on the down hill sections of the line putting energy back into the system to help power trains on the uphill sections of the line helping the heavy coal trains that ran from Wath upon Dearne. DC also was more controllable than AC in the age before the invention of solid state devices i.e transistors. After the closure of the line I understand many of the locos were sold to the Dutch Railways where they ran for many years -

The three day week ,during part of 1974 ,was entirely caused as a direct result of the Miners strike and the need to conserve coal stocks. Therefore electricity ( then almost entirely generated by coal) was effectively rationed for commercial use. Interestingly, in some industries, the affect on output of the 3 day week was none existent. Production levels remaining the same...Proof of Parkinson's law maybe? I think you are confusing your decades regarding unemployment. The 80's were much, much worse. In 1971 unemployment stood at 1 million, rising to 1.5 million in 1978. ( a rate of 5.5%) In 1984 it stood at over double the '78 level with 11.9 % of the working population unemployed. Locally, in 1982, some 2 years before the maximum national number of unemployed, Sheffield had lost at least an additional 20,000 steelmaking jobs and now had 40,000 unemployed...a rate of 13.9% Regardless, the 1970's were good years for many whilst the 80's were horrendous ones for many as well.

-

Found this while doing some research if its of interest to anyone researching mines. UK Coal Mining Data Lots of details on coal mines.

-

Introduction Of Diesel Bus In Sheffield

Unitedite Returns replied to hilldweller's topic in Sheffield Buses, Trams and Trains

Creosote is just another hydrocarbon derivative that would have been readily available at that time, as it is and was, a by-product of coal-gas and coke manufacture, both common enough industries back then. Creosote in its primary distilled form is a thick, oily liquid, though still readily combustible, like most hydrocarbons. However, when generally sold for retail, or industrial uses, it is usually diluted with other, more free-flowing hydrocarbon based solvents, in order to make it easier to use. Benzene, Toluene, Xylene, Ethyl-benzene most probably. These other, hydrocarbon based solvents, would also be by-products of coal-gas and coke manufacture, again, readily combustible, and in some cases more so. So it is probable that what they were really after, were these diluting solvents. So, you could most certainly use such a mixture in an internal combustion engine. Certainly an impressive piece of lateral thinking on the part of Sheffield Corporation Transport, but I would imagine that Revenue and Customs might not have been too impressed had they known, as it does sound a little akin to using red diesel on the public highway. -

Introduction Of Diesel Bus In Sheffield

Keith_exS10 replied to hilldweller's topic in Sheffield Buses, Trams and Trains

Looking back over the various posts it occurred to me that there were a lot of loose ends regarding the producer gas buses. I thought there might be a few problems because of the time lapse back to 1934-1944; in fact there proved to be more than I expected for this period only. As of now, far from being dead, producer gas is alive and well and well documented, being used in places like India and Brazil using biomass, dried bio waste, wood chips or anything carbon based where coal is scarce or hard to come by. It is used on constant speed stationary applications like pumping in gas turbines or reciprocating engines designed specifically for gas power. . So far however there is silence on transport applications. There a flood of literature including academic research results and some unexpected odd contributions by the United Nations Food and Agriculture Organisation. Reverting to this thread re World War 2 there are odd bits to be picked out of many sites but because of the time lapse I have not yet found any drivers experiences; only those of passengers reminiscences passed down from years back. Equally very few performance figures have survived but the views of transport managers have. There are references to early trials but the Birmingham trials of 1934 using very high pressure compressed gas can be discounted. The continentals were at it and Germany quoted 500000 units in wartime use including motorcycles The U.K. government had already distributed 3000 producer gas units round the country in 1938. In 1942 questions were asked in Parliament as to why only a few hundred were in use, the answer being that operators had bought them as insurance in case of war. Supposedly at the beginning of the war the C.E.O. of the Tilling Group persuaded the government that producer gas would be a Good Thing, but I have my doubts as the gas units in were production and out to users. The government had an overall target of 10000 and issued a directive to all U.K. operators telling them to start converting with a fleet target of 10 percent, Originally there were one or two variants mounted either on wheels or fixed somewhere around or behind the vehicle on brackets. The photo of the London bus is the ultimate government standard so we know why they all looked alike whoever made them. Oddly enough by some legal quirk this instruction was also binding on Australia who dutifully complied. The system was essentially a closed vertical furnace with an airtight lid and was filled to the top. Anthracite was the fuel of choice as being over 99 percent carbon. Although only available from a small number of pits in the Swansea area supply does not seem to have been a problem. Australia used wood chips.The furnace had air inlets near the base, solid bottom, no fire bars or similar. The gases went up and out through a grit filter and a minute water wash to catch any acid or tar vapours and was then piped to the engine. To start up, light oil of any sort was poured over the fuel, slight pause to let it penetrate, then ignite it and put the lid back on. Running the engine provided the draught for the fuel which only burned in a ring at air intake level. From start it was reckoned that the system was in full going order in about 12 minutes. One filling was good for 80 miles or so, but no figures for what weight of fuel that was. Some operators did carry extra on the bus. As an example of deterioration of information over time, one eminent preservation body calls it producer gas but then describes making water gas. Another journal roundly states that only petrol engines could be converted. Enough said. Dealing strictly with the common simplest system of hitching the trailer on and piping in, both petrol and diesel engines had a T piece with flap valve let into the air intake plus other odd driver controls. Both types as boginspro has quite properly posted were run as dual fuel engines but slightly differently. A petrol bus was started on petrol, the driver then opening the gas flap valve and actually closing the petrol feed by an additional tap operated from the cab.. Ignition of the gas thereafter by the built in ignition system. After this it gets hazy. There is a reference that once running on gas that was it for the journey. Whether there was ever any use of both fuels together is not stated. . By implication the throttle pedal was used as normal. The diesel engine also had a T piece let into the air inlet but which had a driver controlled flap valve in both arms. To provide ignition the engine ran all the time on a minimum of about 12 -15 to a maximum round 40 percent diesel, the remainder being producer gas.Again there are only sketchy operating details but presumably the gas valve was fully open. We are left to assume that the throttle pedal was used conventionally except that seems to negate the idea of saving diesel. There is no indication that the gas line valve was used to control the speed level.. Confusingly there are some instructions for no reason that makes sense to me for turning corners by shutting the gas off and doing right or left turns on diesel, remembering to turn the gas back on afterwards.and adjust the air valve as necessary. There are two major drawbacks to the system. Firstly there is the engine. A petrol engine compression ratio is too low for gas which lowers the power output. A modern high efficiency diesel would be too high.The WW2 diesel was thought to be only slightly over, but lead to some combustion problems. This whole situation was simply dealt with by ignoring it. Producer gas is rated as a Low Calorific Value Fuel for a start. A good ratio in the producer gas was 35 percent combustible and 65 percent nitrogen compared to 100 percent with liquid fuel. In use the gas is further diluted with nitrogen from the combustion air so the overall power loss was finally reckoned to be at best 30 percent or up to 40 percent on a bad day. Not helpful looking hopefully up the climb to Meadowhead. The diesel seems to have come off slightly better when hillclimbing. The air line flap valve was used to give smooth running and maximum power depending on the fuel/gas ratio and seems to have needed frequent adjustment Service stops needed to have the engine running fast to keep the draught up and don't let it go out on a layover at the terminus. That had to be a loop; no backing with a trailer. The one good thing was that the fire was self regulating by the induction suction and needed no attention from the driver. Then there is the end of the day's work. A dedicated maintainance unit was required Each day the furnace had to be cleaned out and refuelled. The grit filters were cleaned and the water wash checked and filled.. One check with the system working was to test the piping for leaks with a flame. A little blue flame at a joint indicated repairs were needed. All extra work. Engine problems are conjectural in my mind. The lack of lubricity by using gas in the cylinders is mentioned but not stressed though one source claimed a total engine failure after three months service. Another point stressed but nothing more was increased wear due to more bottom gear work.There are some references to problems with the gas trailer itself but again nothing specific. Sheffield converted two petrol buses, the first being a singledecker with the gas plant inboard at back of the saloon which must have made life interesting. Seating dropped from 32 to 20. It had the usual power problems and was banished to the Stannington route where it apparently coped as in 1942 it was reported to have done 20000 miles at lower (unspecified) running costs. The second bus was a double decker, converted once, had a unit change and quietly soldiered on. Eight diesel buses were then converted to have trailer units with a ninth in prospect that never got done. Reading the literature one thing which has survived is the general dislike due to lack of power and inability to climb which transport managers were not backward at saying. There are nationwide reports of stalling on hills, male passengers then having to get out and walk or all passengers having to walk uphill. No record of actual pushing though. Very rapidly where possible the gas buses were drafted to flat routes to get some use out of them. One odd record which has baffled me is the statement that the bus he was on "had to pause to get more gas into the bag before it could go". Not Sheffield I hasten to add. I cannot see how engine suction gets gas into a big roof storage bag. Was it perhaps a straight town gas conversion mistaken? I found no reference to a two gas set up. The complaints carried on and Sheffield Transport decided enough was enough and said as much so the ninth conversion never got done. Boginspro's post suggests the costs were abysmal. Rather surprisingly perhaps I found no direct emphasis or specific figures on the cost aspects. Certainly there were no records of miles per lb. versus miles per gallon. There are published figures of calorific values for anthracite, producer gas, diesel and wood but I admit to coming to a halt in trying to compare a gas with a liquid. Possibly the fact that the buses did provide a service of some sort in the war was recognised but my impression is that the lack of power took precedence over all else. For whatever reason the government in 1944 cancelled the conversion instruction. By all accounts the conversion back to whatever had been was done very rapidly. Think about it; remove the trailer and disconnect the gas pipe at the engine. Anything extra to choice and it might never have happened. What I expected to be a reasonably straightforward search wasn't. The information is scattered and sometimes dubious or impossible or useless. One slightly promising post further north of a late return home by gas bus turned out to be due to a flat tyre. My regret is the absence of first hand driving facts. Driving a diesel/gas bus appears to have been fairly complicated due to the need to keep adjusting the air and gas valves , a point not missed by one manager who declared it took "an extraordinary man to drive one" Probably experience counted for a lot. I doubt now if we shall get to know how difficult it really was and was it a problem. Apologies all round for having to assume and presume here and there. More hard facts would have been useful. And it's left one more question of the same era. Sheffield got complimented on keeping services going by buying creosote from Leeds and using it to dilute the diesel. What do we know about that? -

MY FAREWELL TO THE SHEFFIELD MANCHESTER ELECTRICS - CONGREVES 1970

RLongden posted a topic in Sheffield Buses, Trams and Trains

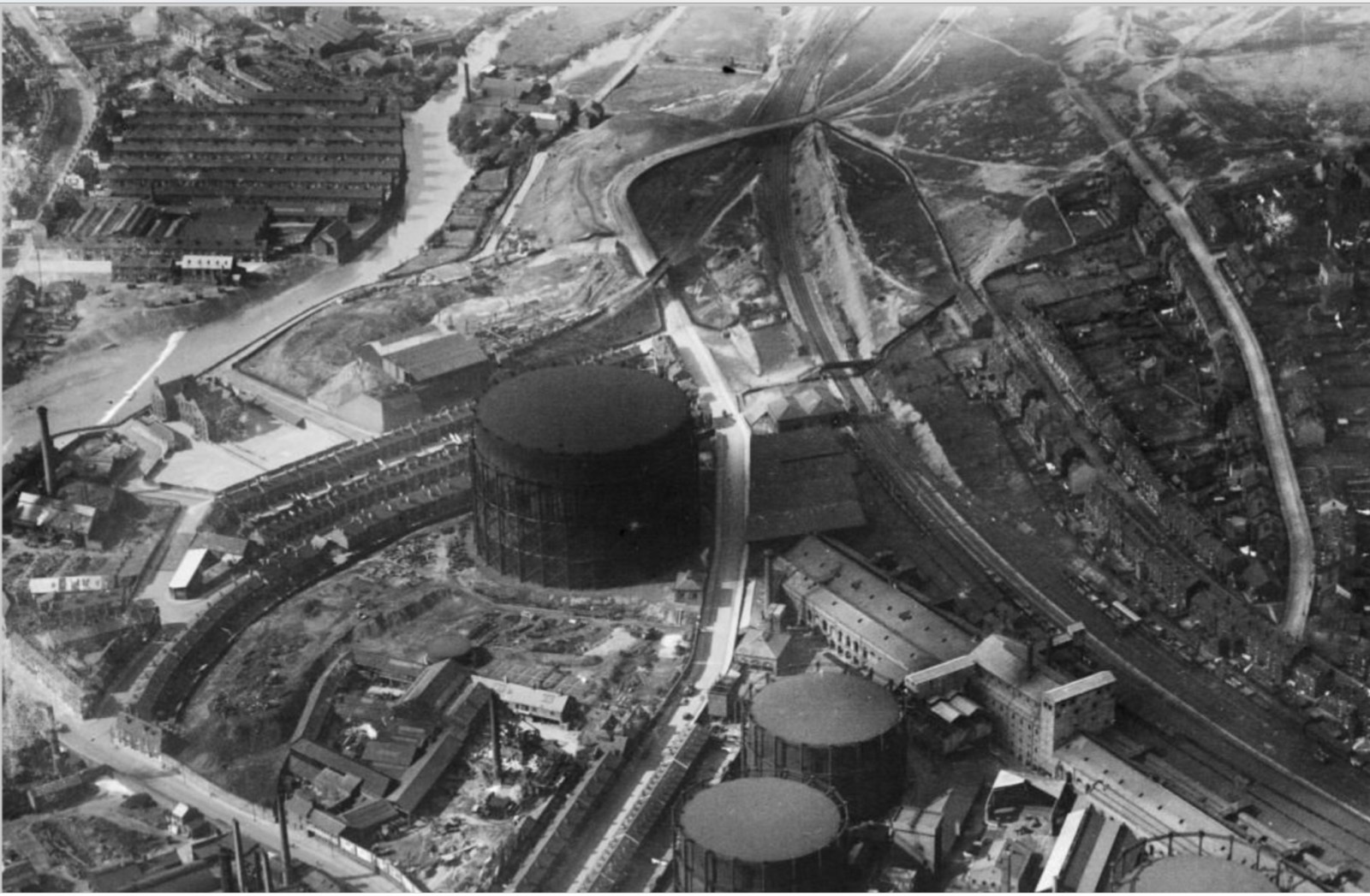

http://www.yorkshirefilmarchive.com/film/my-farewell-sheffield-manchester-electrics-congreves This is a film which shows the last journey by passenger train along the now closed route from Sheffield Victoria Station to Manchester. The film begins showing the overhead electric cables and then a train quickly passing over the camera, followed by the title: ‘My Farewell To The Sheffield Manchester Electrics’. The film then shows some buildings and a sign for Sheffield Victoria Railway Station, followed by the inside of the Station (though it is very dark). Propped up on the outside of a moving passenger train, the camera shows the train departing. The train is then shown from the side of the track passing by. It is being pulled by a diesel engine even though electric cable runs overhead. The route shows the Wicker arches, Neepsend, and Five Arches viaduct. Two tall chimneys are in the background, and from a moving train it passes cooling towers and sidings with coal wagons. Then, from high above on the hillside at Owlerton, a train is shown passing. The film shows inside the signal box at Wadsley Bridge with the track diagram, and a diesel pulled passenger train passing the box, followed by a class 76 electric. From the camera on the moving train the film shows the train passing Penistone Station, on to Dunford Bridge Station, into Woodhead Tunnel and leaving the Tunnel at Woodhead Station. Having left the tunnel the train passes reservoirs and the surrounding wintry countryside. It also passes over a viaduct, Crowden Signalbox, the sidings at Dinting, Mottram and Broadbottom Stations, and through Godley Junction, before the film comes to an end. Further reading... click on 'context' tab on linked webpage -

I remember when working in Tinsley in the 60's/70's that Blackburn Meadows Power Station was fuelled by coal. I say that because of the grit and smoke emanating from its chimneys. On checking I see It closed in 1980 and was still coal fired. In the 1950's we still had clothes rationing and people had far fewer clothes than today as a result clothes were looked after! The fashion, even into the 1970's, was for people, especially men, to dress "smartly" refraining from looking "casual" except for leisure.

-

Pedestrians and Traffic 1950

Unitedite Returns replied to madannie77's topic in Sheffield History Chat

Coal was still the principle source of heating used in most households at that time, gas was still produced from coal, most electricity power stations were gas-fired, the principle form of propulsion on the railways was still steam generated from coal, as was indeed, the energy source that powered most of those industries still prevalent at that time, and indeed, some of the fuel used in internal-combustion engines was being generated from coal-shale. The first clean-air act wasn't passed through parliament until 1956, so I suppose that some haze would have been present in most major conurbations most of the time. However, you certainly do get the distinct impression, that when in public, that there was a tendency for people to pay much greater attention to their appearance than perhaps we do today. Brilliant footage by the way. Much enjoyed watching it. -

Once Upon a Time - When We Could Actually Make Things

Athy replied to Unitedite Returns's topic in Sheffield History Chat

Quite so - if your factory's in the middle of a coalfield and your lorry burns coal, it does seem logical. Am I right in thinking that the fleet lasted until the end of Brown Bayley's works? Steamers apparently retained their popularity as brewers' drays long after they had largely been superseded by internal-combustion lorries in other spheres of transport. -

Washing day on Woodgrove Lane

Unitedite Returns replied to Sheffield History's topic in Sheffield History Chat

Wash-day in my maternal grand-father's house was on a Saturday morning, the significance of which I have never thought about before, but that is probably explained by the fact that he was a coal-miner. I remember that they possessed a fear-some, free-standing, electric motor powered roller-ringer, which looked more than capable of forming inch-thick armour-plate. The upside of this unusual schedule was that with the coal-fired range on full throttle, in order to produce sufficient hot-water, that the ovens were used, at the same time to cook the most wonderful rice-puddings, with thick, tasty skins on-top. In my parents' house, wash-day, was, for many years, on a Monday, a convention that remained unchanged for long after the introduction of modern domestic appliances, probably because that was the way that it had always been done. Today, we just bung the washing into the washer-spinner-dryer, and let the machine 'do-its' own thing' whenever the inclination takes us. String-beans however - horrible, nasty things, that we kids always avoided. POSTSCRIPT: By the 1970's, you could tell as to whose father worked where as to the design and colour of the 'acquired' ex-works towels hung to dry on the washing line. Now the guy who worked in the stores, his washing line could have rigged a clipper-ship.